|

|

.

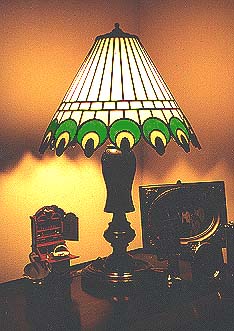

This is a leaded lampshade. Leaded

glass lampshades are much less common than copper

foiled ones because a leaded shade is constructed flat, then bent into

its final shape (pure lead being a very soft, bendable metal). This

requires wrestling with the mathematics, and also involves the skill of

bending and joining the sections in a fluid manner such that the "seam"

is indistinguishable from the rest of the shade. It was fortunate that

when I started working in glass as a child, the uncle who got me

started in stained glass had been taught the skills involved in

producing leaded shades, and passed those along to me. The major

advantage of leading a shade is the uniformity of line that is achieved

with the pre-formed lead, as opposed to copper foil, which can never be

as uniform even when the cutting of the glass is very precise. Also,

many copper foil shades nowadays are store-bought kits, although that

does not imply that they are simple to do. There are no kits for making

leaded shades (that I have ever heard of). This is a leaded lampshade. Leaded

glass lampshades are much less common than copper

foiled ones because a leaded shade is constructed flat, then bent into

its final shape (pure lead being a very soft, bendable metal). This

requires wrestling with the mathematics, and also involves the skill of

bending and joining the sections in a fluid manner such that the "seam"

is indistinguishable from the rest of the shade. It was fortunate that

when I started working in glass as a child, the uncle who got me

started in stained glass had been taught the skills involved in

producing leaded shades, and passed those along to me. The major

advantage of leading a shade is the uniformity of line that is achieved

with the pre-formed lead, as opposed to copper foil, which can never be

as uniform even when the cutting of the glass is very precise. Also,

many copper foil shades nowadays are store-bought kits, although that

does not imply that they are simple to do. There are no kits for making

leaded shades (that I have ever heard of). |

Return to the

Gallery

|